This wind tunnel was designed in the Institute of Thermomechanics CAS between 2000 and 2002, and has been operational since 2004.

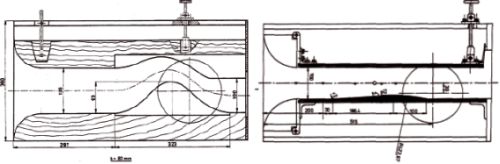

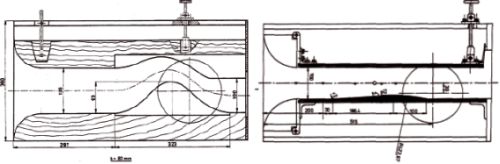

Schematic of the Modular wind tunnel

Schematic of the Modular wind tunnel.

Air enters through a silicagel dryer and pebble and cloth filters 1 into the entrance room, and then through honey-combs and settling screens 2, 3, and 4, into the contraction 5, and a straight test section modulus 6. Further downstream are a transitional element 7, compensator 8, 9, pipe 10, control nozzle 12, bellows 13, spherical fast-acting gate 14, hand-driven closing valve 15, diffuser 16, and connection to the main duct and the vacuum storage.

The modular wind tunnel with a straight closed test section and the optical bench.

The modular wind tunnel with a straight closed test section and the optical bench. With a special test section for radial inflow turbine cascades it is possible to carry out experimental investigation of radial turbine cascades, including flow visualization and loss measurements using a special traversing mechanism, moving the traversing probe on a circular path behind the cascade.

|

|

| The modular wind tunnel with a test section for radial inflow turbine cascades, and with the traverzing mechanism. |

The uncovered traversing mechanism. |

In the modular wind tunnel it is now possible to carry out experiments of quite fundamental character, for which in the past we had a small high speed wind tunnel attached to the main duct by a 300mm pipe and quick operating valve. This wind tunnel was dismantled, though most of our experimental investigation of the flow in relatively narrow channels had been made in it.

It was used mainly with one-purpose test sections, and test sections with variable width, to study the flow separation, quantitative and qualitative changes in the terminal shock wave – boundary layer interaction, transition from supersonic to subsonic flow in narrow channels in a pseudoshock wave, the effect of flow non-uniformity on the transonic flow in the critical cross section, flow past blunt trailing edges, etc. In most of the cases the width of the test section could be changed in the range from 10 to 120 mm (see figure below).

Test sections for the small high speed wind tunnel.

Test sections for the small high speed wind tunnel.