X-ray powder diffraction is a basic analytical tool in material science for phase identification and characterization. It is a non-destructive method with easy sample preparation and mounting. Small quantity of sample (0.1 cm3 of powder volume) is sufficent for measurement in the standard sample holder, but basically any amount can be analyzed as well using special holder cut from silicon single crystal.

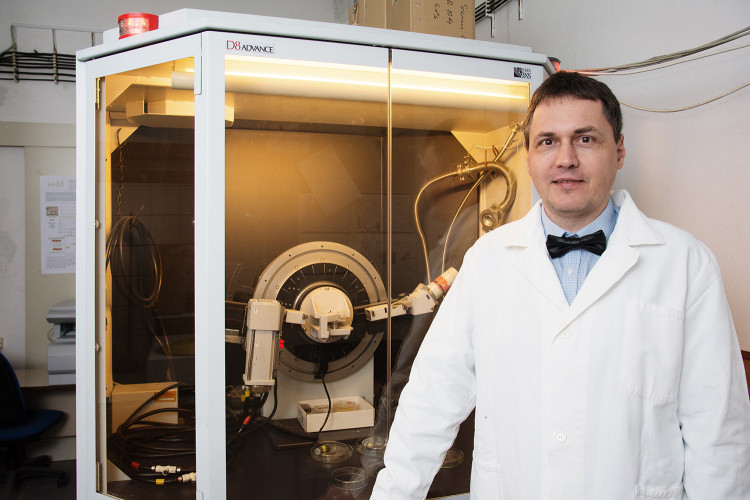

X-ray powder diffractometer Bruker D8 Advance (CuKα radiation) was installed in 2001.

|

|

The principal task is an identifications of crystalline phases in multiphase sample with the help of crystal structure database ICSD.

Molar ratio of phases with known crystal structure is calculated by whole pattern fitting using FullProf suite based on the Rietveld method. The powder diffraction is the most accurate method for calculation of lattice parameters. The Rietveld method is further used for refining the crystal structure, i.e. atom positions and occupancies, of the identified phases. The modulated structures are solved by JANA program. The determination of the crystallite (grain) size of nano-materials (over the range approx. 3-300 nm) is based on the analysis of the peak broadening. Thompson-Cox-Hastings pseudo-Voigt profile is used to resolve instrumental, strain and size contributions. Instrumental resolution is determined by measuring strain-free tungsten powder with grain size 9.4 µm. Preferred orientation (texture) of solid samples (pellets) or thin films can be analysed by the rocking-curve method.

The temperature dependent structural characterization over the range 90-1200 K is realized using MRI TC-wide range temperature chamber (Bruker XRD Non-ambient Stages). The measurements can be performed under ambient atmosphere, vacuum or flowing gas. Two scans are typically measured for each temperature and the measured intensities are compared in order to check the thermal stability and reproducibility of the sample structure.

Kalvados software was developed in our laboratory for working with powder diffraction data and crystal structure files.

Contact person: Karel Knížek

Copyright © 2008-2014, Fyzikální ústav AV ČR, v. v. i.