Optical diffractive structures

|

The group of Electron Beam Lithography (EBL) within the Special technology department developed the E-beam lithography technology and Optical diffractive structures.

|

|||

|

Bragg grating sensor prepared form the diffractive photomask is used for the monitoring of containment status.

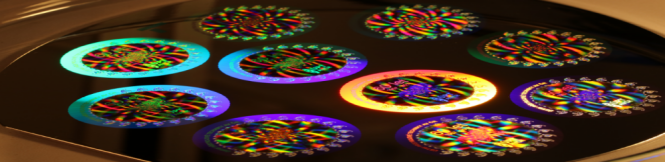

DOVID master.

Diffractive zonal lens. |

The resolution of the e-beam writer for the delineating of gratings with a period below 1 micron which is close to the visible light range (400–700 nm). With a relatively high writing speed, optical diffractive structures up to several inch squares can be prepared. Due to the flexibility of the technology a variable set of diffraction gratings as well as their combination within one sample is possible e.g. reflection or transmission gratings, phase or amplitude gratings, regular (lines, crosses, circles) and irregular structures (Fournier, Fresnel), binary and multilevel profile and so on.

Selected R&D result used by industrial partner:

|

The group of Electron Beam Lithography Research areas:

Offered technologies: |

|