IPP launched the production of worldwide unique OVSS steady magnetic field sensors. The sensors will be installed on the ITER thermonuclear reactor in France. OVSS have been developed in the UFP in the wide international co-operation with other scientific institutions and industrial enterprises.

OVSS (Outer Vessel Steady-state Sensors) are designed to measure steady-state magnetic field

under extreme conditions of thermonuclear reactors. In the near future, they will be installed on

the ITER thermonuclear reactor being constructed in France, which will be the world's largest

nuclear fusion research facility. Sensors were developed at IPP in Prague in extensive

international cooperation with ITER International Fusion Energy Organization (France), Institute of

Physics of the CAS, Institute of Nuclear Physics of the CAS, Research Center Řež, Petr Sládek, HVM

Plasma Ltd., Plasma Technologic Ltd., PragoBoard Ltd., AVS Added Value Industrial Engineering

Solutions SL. (Spain) and LT Calcoli Srl. (Italy). The whole production process will be managed and

coordinated by IPP .

Photo: Slavomír Entler, IPP.

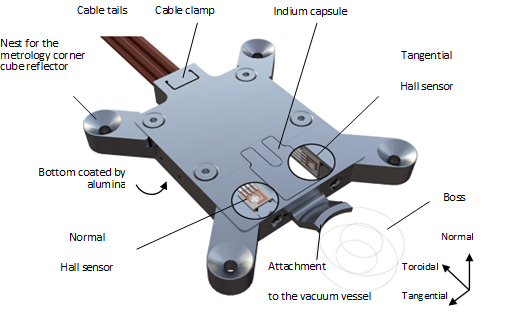

The Hall sensors will be installed in the ITER reactor in three

sectors of the vacuum chamber. In each sector, 20 sensor units will be deployed, containing a pair

of sensors positioned perpendicular to each other to measure the tangential and normal component of

the magnetic field. The sensor operating temperature will be 90-100 °C, while the sensor

temperature can reach up to 220 °C during the vacuum vessel baking. Total neutron fluence over the

lifetime of the sensor reaches approximately 1.3x10

22 n/m

2.

Photo: Slavomír Entler, IPP.

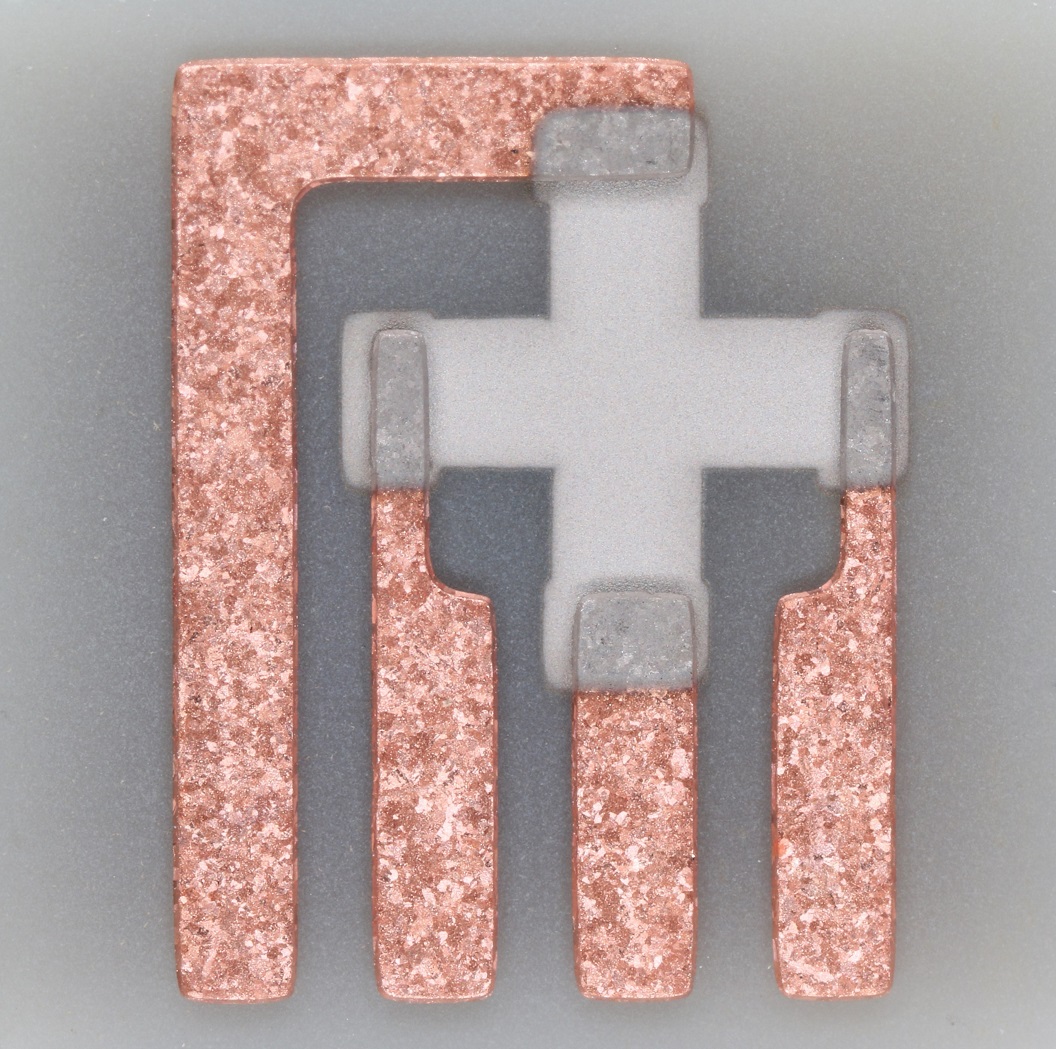

Developed Hall sensors are 6.4 mm x 6.4 mm in size and consist of a 0.63 mm thin ceramic

plate. On the ceramic plate, a copper layer of 127 μm is applied using Direct Bonded Copper

technology. The bismuth detection layer is deposited by magnetron sputtering and has a thickness of

1 μm. The sensors will be placed in pairs in the stainless steel sensor units. The sensor assembly

also includes a control unit that processes the sensor signal. The measurement error of the sensor

assembly is 0.1% in the measuring range of ± 2.5 T.

Picture: ITER Organization.

7 Feb 2018