Laboratory degradation of building materials and structures

Ústav teoretické a aplikované mechaniky › CET › About CET › Laboratories › Laboratory degradation of building materials and structures

People

Head of Laboratory: Ing. Jiří Frankl, Ph.D.

+420 604 134 567

Members of laboratory: Ing. Kateřina Kreislová

Mgr. Dita Machová

Ing. Dušan Majtás

Research activities

The laboratory is focused on studying the processes of degradation and changes in mechanical properties of building materials and components due to biological factors and is equipped for climatic and corrosion test on wide variety of materials. The department is able to provide combined tests using several testing procedures and chambers, test according to ISO standard or test directly prepared for given set of samples and also a wide range of analyzes to determine the type and activity of pests, extent of damage and the causes of its origin. Laboratory equipment allows identification and cultivation tests damaged building materials (wood, stone, concrete, etc.) with different types of microorganisms (fungi) and organisms (fungi, algae, lichens, etc.). In relation to other work centers of excellence , it is possible to monitor the impact effect on biodegradation properties of building materials.

Equipment and instrumentation

Climatic nd corrosion chambers:

• Xenon chamber simulating exposition to sun-rays combined with rain simulation by DI water

• Climatic chamber with controlled temperature and humidity; lowermost level -40°C, test space 200 litters

• Climatic corrosion chamber with artificial atmosphere, controlled temperature and humidity; test space 600 litters, two separate gas inlets

• Salt-spray corrosion chamber; test space 450 litters

Our laboratory is suitable for testing small scale samples. As a rule of thumb we are not able to test samples larger than 500x500x500mm. The size may differ per chamber type. Test space geometry is specified in the following tables.

Xenon chamber – artificial sun (QSun-Xe3-HS)

|

Temperature range – test space

|

+20 ~ +65°C

|

|

Temperature range – black panel

|

+50 ~ +90°C

|

|

Lighting intensity

|

0 ~ 2,0 W / m2

|

|

Relative humidity range

|

10 ~ 98% RH

|

|

Light source(s)

|

3 Xe lamps

|

|

Test space configuration

|

Sloped flat panel

|

|

Water consumption – Sprazing system

|

0,3 l/min (0,1 l/min - mean value)

|

|

Water consumption – Humidifier

|

0,1 l/min

|

|

Test space

|

715x450 mm (W x D)

|

|

Test space height

|

200 mm

|

The above described three lamp configuration does provide comparable results to one lamp carousel sample holder configuration chambers. Multiple lamps does provide homogenneous light concentration over the test space. The chamber is compliant with same standards the one lamp and carousel configuration is.

Climatic test chamber (CTS C-40/200)

|

Temperature range

|

-40°C / +180°C

|

|

Temperature fluctuation

|

±0,3°C

|

|

Temperature change - heating

|

+3,5°C

|

|

Temperature change - cooling

|

-4,0°C

|

|

Relative humidity range

|

10 ~ 98% RH

|

|

Dewpoint (range I)

|

+7 ~ +94°C

|

|

Dewpoint (range II)

|

-10 ~ +7°C

|

|

Dewpooint fluctuation (range I)

|

±1,5°C

|

|

Dewpooint fluctuation (range II)

|

±3,0°C

|

|

Test space in litres

|

200 l

|

|

Test space dimension in mm

|

750x650x400 mm (H x W x D)

|

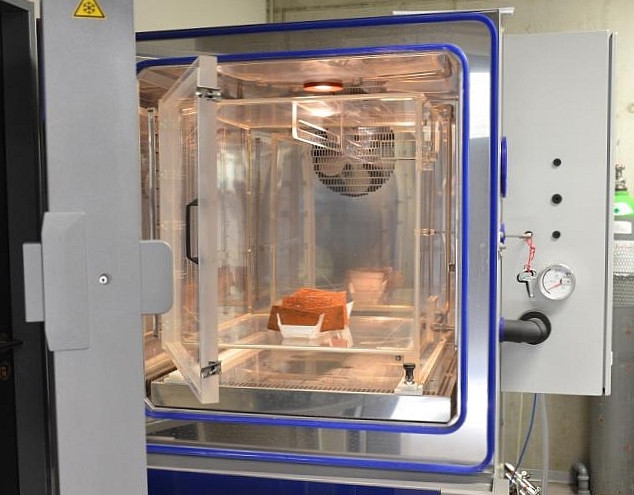

Climatic test chamber CTS C-40 (right) and Xenon chamber – artificial sun QSun-Xe3-HS (left)

Climatic - Corrosion test chamber (CTS C+10/600-SG)

|

Temperature range

|

+10°C / +60°C (+90°C)

|

|

Temperature fluctuation

|

±0,3°C

|

|

Temperature change - heating

|

+3,5°C

|

|

Temperature change - cooling

|

-3,5°C

|

|

Relative humidity range

|

10 ~ 80% RH (up to 98% when used as climatic chamber)

|

|

Dewpoint (range I)

|

+7 ~ +94°C

|

|

Dewpooint fluctuation (range I)

|

±1,5°C

|

|

Number of inlet gas valves

|

2 (of 4)

|

|

Gas inlet dosage

|

0,15 ~ 15 ml/min

|

|

Corrosive gasses used

|

1% of NO2 in Nitrogen gas

|

|

|

5% of SO2 in Nitrogen gas

|

|

Test space in litres

|

600 l

|

|

Test space dimension in mm

|

850x850x830 mm (H x W x D)

|

To control the climatic-corrosion chamber, the laboratory's employee Ing. Majtás developed a special application GasFlow. To know more about the application and its download, click here.

In addition to corrosive gasses mostly used in our laboratory (SO2 a NOX) it is also possible to use other corrosive gasses (Cl2, O3, H2S…). All gasses used are in mixture in nitrogen of concentration up to 15% max. (stored in the pressurized cylinder). The chamber is suitable for test in low concentration of corrosive atmosphere where concentration of one corrosive component does not exceed 25ppm in the test area. Test in the high concentrations of corrosive gasses could not be realized using this chamber.

When different gas is ordered there are several things to be kept in mind. First it is possible to prepare mixture of several corrosive gasses in one pressurized cylinder; unless not possible to achieve due to physical or chemical properties and behaviour. Second the time required for obtaining the new set of pressurized containers is approximately 2 months.

Lower limit of dosage into the chamber should be 0ml/min technically, but in reality feedback system does not recognize inlet flow lower than approx 0,15ml/min.

Corrosion Salt-spray chamber (s450ip)

|

Temperature range

|

+20 ~ +65°C

|

|

Test regimes

|

Spraying, condensation, drying

|

|

Humidity regulation

|

Dry state / wet state

|

|

Relative humidity range

|

10 ~ 98% RH per 5% step (logging only)

|

|

Pressurized air source

|

Piston type air compressor with 120l air bag reservoir

|

|

Test space

|

950x600 mm (W x D)

|

|

Test space height

|

250 ~ 500 mm by position in the test space (sloped lid)

|

|

Spraying and condensate collection are

|

400mm

|

Apparatus for the preparation of glassware and instruments, processing samples in the field, the preparation of samples for culture and identification tests and tests:

• hood (Merci)

• steam autoclave (Tuttnauer)

• oven (Binder)

• Laboratory balance (Kern)

Incubators culture test samples and growing pure cultures of microorganisms:

• Incubator (BMT)

• incubator with controlled temperature (BMT)

Apparatus for the preparation of microscopic slides and optical microscopes for evaluation of laboratory tests:

• microtome (Leica)

• stereo microscope (Olympus)

• research microscope (Olympus)

Example output of the laboratory:

Processing wood sample taken from the component damaged by decay fungi (rot) - determine the gender classification of active wood-destroying fungi and their activities .

wood sample taken in the field of control activities damaged wood-destroying fungi |

placement of grafts wood on sterile gel fertile ground - placed in an incubator - the beginning of cultivation |

growth substrate and aerial mycelia of wood-destroying fungi during cultivation tests |

microscopic evaluation - identification and generic classification of acting against fungi |