People

Ing. Jaroslav Valach, Ph.D.

His main fields of expertise include optical and non-destructive experimental methods for the documentation and monitoring of cultural heritage buildings, objects and materials both in laboratories and in situ and linkage of the measured quantities with computer-aided data processing. He develops this specialization through active research activities and cooperation on a number of both European and national projects. His research activities are complemented by teaching activities - lecturing and advising students at the Faculty of Transportation at the Czech Technical University.

Mgr. Veronika Koudelková

Since 2012 she has been working as a scanning electron microscope operator, studying namely the composition and microstructure of inorganic porous construction materials. In 2014, she enrolled in a PhD program at the Faculty of Civil Engineering at CTU, for which she is specializing in research on crystallization pressures in water-soluble salts.

Mgr. Riccardo Cacciotti

Benjamin Wolf

He focuses on the design and production of special electronic devices, including the design of circuit solutions and PCBs. Furthermore, he occupies himself with the development of software for communication between PCs and these devices with features for variable data storage and for control of these devices through a graphical user interface.

Ing. Jan Bryscejn

He mainly specializes in the creation of libraries, programs and applications for computer-aided image processing and other computationally demanding cases of mass data processing. He also deals with access to GIS and the programming of special interfaces for such systems.

Destription of Activities

As is evident from the name, the Laboratory of Optical Methods and Microscopy deals with the study and documentation of objects of various sizes (from microscopic objects to buildings and structures) using various physical methods. This means that most of the methods used convert hidden or non-recognizable facts to image form. Why is data in the form of image important? The reason is that people are able to perceive visual information, where they can easily find repetitive patterns, differences and identities, which help evaluate the image and its meaning. By combining technical means and evolution adaptation, we can achieve the capability of working in the environment of hidden processes and phenomena not available to human senses; examples include processes taking place on invisible wavelengths (x-ray radiography or thermal radiation in infrared thermography) or on extremely small scales (microscopy) or at such speeds that they cannot be noticed in common ways, requiring the use of the time magnification features of high-speed cameras and the like. Moreover, by digitizing image data, we are able to handle images as large numerical matrices and quantify the observed processes.

Research and equipment

Scanning electron microscopy

The Laboratory of Scanning Electron Microscopy is equipped with the Bal-Tec SCD 050 sputtering machine necessary for covering the non-conductive surface of the sample with a thin conductive layer of gold or carbon, which is necessary for observation in SEM and the MIRA II LMU microscope by Tescan. This microscope is equipped with a total of four detectors suitable for characterizing the morphology and chemical composition of the studied material. The secondary electron detector (SE) allows the display of the topography of the object being studied, while the reflected electron detector (BSE) allows the distinction of the phases present on polished ground samples based on the sensitivity of BS electrons to the atomic composition. Apart from these two basic detectors, SEM is equipped with an energy dispersion spectrometer (EDS), which allows the qualitative and quantitative determination of the proportion of individual study phases and their chemical composition, and also with a cathodoluminescence detector for the study of the internal structure of selected geological materials.

The microscope makes it possible to work in the acceleration voltage range of 1 kV to 30 kV; lower acceleration voltages are suitable namely for sensing surfaces that are highly sensitive to electron beams. SEM can only be used to study dry samples without free water content because the microscope chamber reaches high vacuum levels.

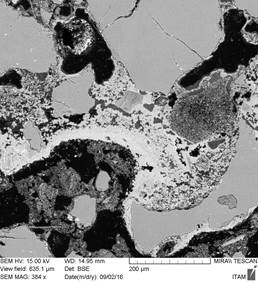

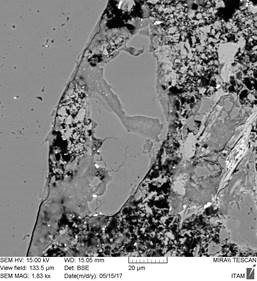

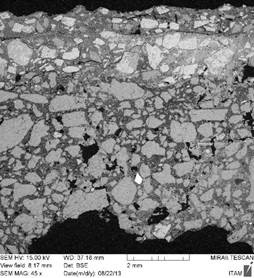

The SEM laboratory namely addresses the characterization of porous construction materials, which often include historical mortars. When analyzing polished ground mortar samples, we mostly focus on determining the granulometry and type of aggregate, porosity, binder type and hydraulicity and on observing the various textural and structural characteristics that allow the description of the conditions which could influence the mortar during deposition.

|

|

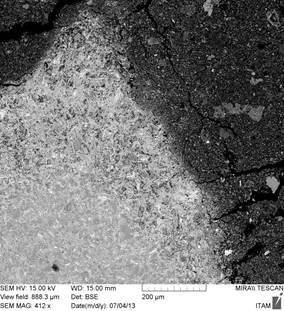

| Carbonation (the lightest area in the center of the sample) on the surface of old mortar, which was later covered with a newer layer of mortar. | Dissolving quartz grain (center), from which the silica gel is released into the surrounding binder. |

|

|

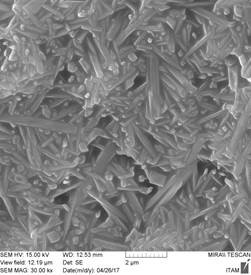

| Micrographs showing that it is possible to sense the sample surface at various magnification rates. The micrograph on the left illustrates a mullite structure magnified 30000x, while the micrograph on the right shows a cross section of the mortar magnified 45x. | |

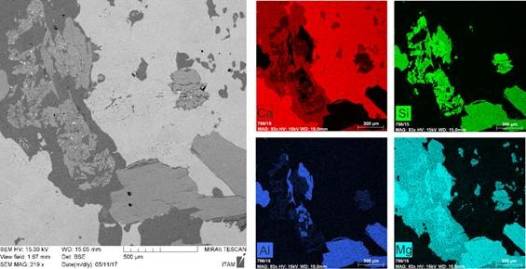

EDS detector enables the creation of colour maps for displaying the distribution of individual elements.

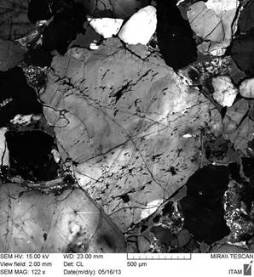

Micrograph showing a quartz grain created using a cathodoluminescence detector.

|

|

| Micrograph and element map of a border created by the reaction between brick grain and the surrounding lime binder | |

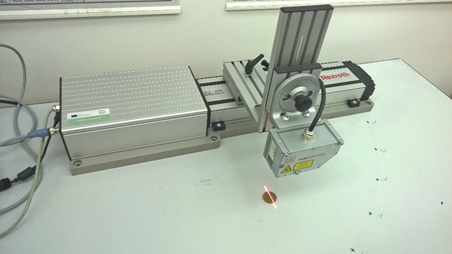

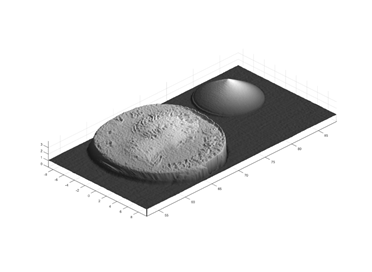

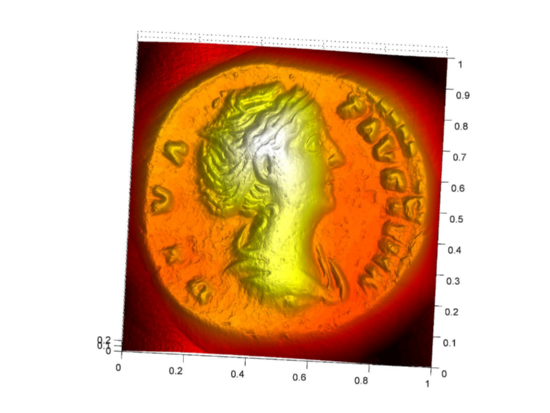

Laser triangulation scanning profilometry

A device for recording surface relief. It uses the triangulation principle, which is implemented by projecting a focused laser beam from the scanning head vertically onto the surface, where it creates a bright spot. This bright spot is detected by the optical system in the inclined direction using a linear photosensor in a manner that permits the determination of a direct dependence between the surface elevation data (distance from the measuring head) and position of the bright spot image on the photosensor. There is a row of 1024 sensors configured in this way to allow scanning. The head itself is position adjustable and motor-driven in a range of 30 cm, offering a spatial step resolution down to 10 microns and height range of the measured surface of approx. 5 cm with a highest resolution of 10 microns. ITAM has developed custom software for this device for the translation of the data into a height matrix, “sewing” data from two concurrent scanned bands and merging the upper and lower scanned surfaces into a single object.

|

|

| Coin scanning with profilometer | Digital 3D model of the coin |

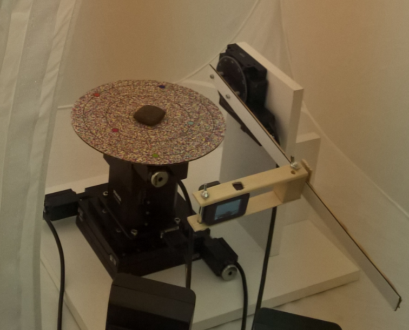

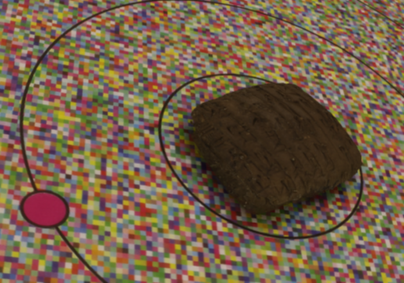

Use of SfM to create digital 3D models of objects

At present, project NAKI2-022 includes work on the development of an automated device for the acquisition of digital 3D models of bodies using the SfM (Structure from Motion) method, a digitizing method currently undergoing rapid development, which allows the reconstruction of an object in the form of a 3D model based on the processing of a series of photographs of the same object taken from different directions and views. The device ensures optimum lighting conditions to eliminate reconstruction errors due to undesirable reflections, shadows and absence of texture on the object's surface. Under these conditions, the surface is scanned by a digital SLR using the automated sequential scanning method.

|

|

| Assembly for SfM with board equipped with a random colour pattern facilitating the use of a reconstruction algorithm and the result for the sphenographic table | |

Photometric stereo

ITAM develops procedures for the digitization of relief surfaces using the photometric stereo method. As the name suggests, this method detects the spatial shape of the given body based on the measurement of light intensity reflected from its surface. How does the photometric stereo method work? The incident light is absorbed, transmitted and reflected by any object. The reflected light conveys information on the surface colours (based on different reflectivity for different colours) but also information on the surface shape, roughness and relief complexity. The term “photometric” means that the method determines the amount of light entering the recording device (e.g. camera) from the given point on the surface being studied. For shape recording (indicated by the term stereo), the basic rule applies that a spot on the surface is apparently the brightest spot under otherwise identical light conditions, if its normal (line perpendicular to the surface) is directed towards the light source. Knowing the light position makes it possible to use the measured brightness of a certain spot on the body surface to determine its inclination with respect to the incident light and to the general coordinate system. Moreover, knowing the normals of surface spots makes it possible to determine the height complexity of the surface. At present, a third generation device has already been developed and patented. The purpose of the device is to automate the process of object recording in optimum light conditions to obtain spatial surface models with the highest resolution available.

|

|

| Equipment for the photometric stereo method and the digitization of one side of a Roman silver coin | |

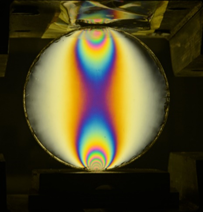

Photoelasticimetry

Photoelasticimetry is an optical method that allows the study and direct visualization of stress arrays inside loaded bodies made of birefringent materials. Such materials include, e.g., glass and certain types of resins and polymers. By inserting a sample of such materials into an optical system with polarizing filters, we can create stress patterns according to the differences in main stresses. The polariscope available at ITAM is a direct successor of a very successful model of this device awarded a gold medal at the EXPO exhibition in Brussels in 1957. This method was very popular in the past, but it was gradually suppressed by the onset and development of computing methods such as the finite elements method. Nevertheless, it still maintains its value for many reasons. For example, it allows the creation of simple yet elegant visualizations of internal stresses in elastic bodies; furthermore, with the increasing use of structural glass in civil engineering, the problem of stress distribution study in such parts is of great importance, and recovery of interest in this method can certainly be expected also because of the development of high-speed camera recording of quick processes, which will make it possible to directly observe the stress distribution on front faces with fragile expanding cracks.

|

|

| Confirmation of boundary conditions for devices studying material tensile strength in the transverse direction. | A photoelastic image of a body in contact with rigid planar supports |

Reflectance measurements

Knowing the surface reflectance (reflectivity) is essential for more than just optical digitization methods. Reflectance expresses the ratio between the amount of incident and reflected light. Its value may vary for different wavelengths, which results in a particular colour and hue of the surface, also for different directions. Examples of extreme cases of such directional dependence include the behaviour of matte surfaces (e.g. interior decoration on walls) and the behaviour of mirror metal surfaces, which only redirect the incident beam in the direction given by the law of reflection. Most surfaces represent “something in between” these extremes, and the variations in their reflectivity can be used as indicators of changes in their micro-topography, because it is roughness in the visible light region which basically determines reflectivity. A device for measuring reflectance has been developed, which allows study in various configurations of angles of incident light and angles of observation. This results in an angular reflectivity map which can be used to document surface changes.

|

|

| Inside the reflectometer with a glass sample | Comparison of reflectance maps for matte and partially glossy surfaces |

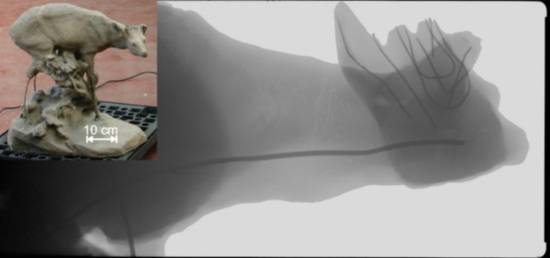

Radiography

Radiographic methods are used to study the sub-surface properties of objects. It is known that short wavelength radiation (e.g. X-rays) is capable of penetrating deep under the surface or through the body's volume; the level of attenuation is proportional to the penetrated thickness and material composition. This makes it possible to “view” cavities and cracks inside bodies as well as inhomogeneous areas in the material (metal reinforcements, etc.). The portable device thus allows non-destructive study of the internal structure and composition of various objects from beam joints to armatures in sculpture socles.

Example of the use of radiography for detecting reinforcements in a concrete sculpture

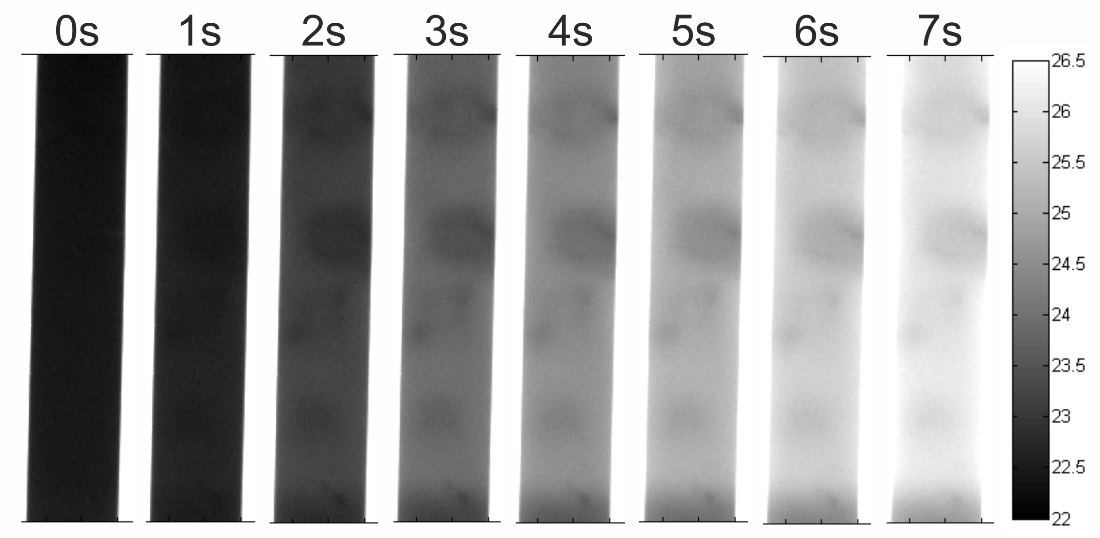

Thermography

We can see the objects around us thanks to the light passively reflected off their surfaces. Apart from this reflected light, objects generate thermal radiation, which usually lies in the region of invisible electromagnetic radiation - exceptions include, e.g., radiation from the surface of the Sun and radiation from an incandescent wire in a bulb or red hot metal drawn from a forge. At the temperatures we commonly live in, objects generate radiation in the wavelength region with the maximum number of micrometers that can be detected by thermal imaging cameras. This means that the sensor chip of a thermal imaging camera works like an extensive matrix of thermometers which record the temperature distribution on the surface of the object being studied. The thermal imaging camera FLIR SC7600 offers good spatial sensor resolution (640*480 px) and also a temperature resolution under 1 mK and a relatively high recording rate (up to hundreds of frames per second). Inhomogeneities in the temperature field thus indicate inhomogeneities in the superficial or sub-superficial layers and, as such, can be used for the non-destructive study of many objects and processes. Using this method, we can, e.g., visualize moisture in masonry, plaster separated from a wall, or spots in a composite material sample, where the largest amounts of heat are generated by internal friction under fatigue loading and which, therefore, are subject to the fastest deterioration.

|

|

| A simple assembly for the detection of internal damage in carbon composite using differences in the thermal conductivity of the damaged areas in the band sample. The sample was placed on the surface of a tank with hot water, separated from the water by a thin film. The temperature increase was monitored by a thermal imaging camera. The damaged spots remained cold the longest. | |

High-speed cameras

High-speed cameras make it possible to study processes with a time magnifier - by stretching the event over a longer time interval, where the human senses are able to distinguish the sequence of the individual events the process is composed of. For example, we can use a high-speed camera to monitor the movement of a Charpy hammer during an impact test to study the sample breaking process and get more information about it. The Flatron SA5 camera, which is available at ITAM, can record with frame rates of up to 10,000 frames per second with 1MP resolution, or even one million frames per second with a reduced field of view. Innovative applications of high-speed recording include the study of material surface wettability through the determination of the surface hydrophilicity or hydrophobicity based on the dynamical parameters of drop reflection.

Charpy hammer equipped with a high-speed camera

Ultrasound

Non-optical methods for material and object study include namely measurements of ultrasonic wave propagation rates in materials. Knowing the density of the material under consideration, makes it possible to derive the dynamic modulus of elasticity, which is an important indicator of coherence and quality, particularly in natural building materials (stone, wood). The equipment provided by Geotron has recently been enhanced with a computer connection, which allows not only the digitization of pulse records but also the equipping of the device with instrumentation for long-time recording at specified time intervals, which - in combination with automated record processing - allow the monitoring of changes in material properties in time; examples include carbonation, solidification of components, changes due to increased moisture content, etc.

An ultrasonic set with probes for measuring wave velocity at selectable depths, which allows the study of changes in material properties at various depths.

Projects

On-going

NAKI2-022 The analysis, description and archiving of aggregate information on the properties of cultural heritage objects and the practical use of this information for restoration, preservation and research

The project objectives include the design and development of devices and systems for the documentation and analysis of collections based on computer-aided visualization and documentation methods and the practical demonstration of their functionality on the digitization of thematic groups of cultural heritage objects. The digital models of collections that are created shall be complemented by information and findings in the form of database records; this information shall be acquired using non-destructive analytical methods (e.g. information on the internal structure, topography, external appearance and element composition of the surface) with annotations consisting of meta-information. This information, combined according to purpose, will allow not only continuous monitoring of surface degradation and detection of possible internal defects but also (in combination with other data) new findings on object development or previous preservative or renovative interventions. Information on composition will be acquired via analyses such as those commonly used in the humanities (historical/archaeological/linguistic/palaeographic, etc.). Within the proposed, purely interdisciplinary project, specialized devices are being developed and various tools are being used for the semantic, visual, spatial and compositional documentation of collections to obtain the maximum amount of information that can be used in practice in the fields of renovation, preservation and, last but not least, research.

GAČR P105/12/G059 Cumulative time-dependent processes in construction materials and structures

The project addresses the assessment of long-term monitoring of environmental influences on selected materials and structures, the consequences of moisture and salt penetration into porous materials, problems with fatigue due to climatic load, and methodology for material and structure assessment in terms of risk reliability.

Completed

NAKI001 Diagnostics of the damage and life of cultural heritage objects

The project objectives included the development of new instruments and associated non-destructive and slightly destructive methods for diagnostics of historical surfaces and the validation of their applicability to the study of the conditions of historical materials and structures as well as quality control and control of the efficiency of renovation and preservation work.

NAKI002 Defects in immovable monuments: knowledge system for analysis, intervention design and prevention

The project aimed to build a knowledge base for documentation and the analysis of defects of cultural heritage buildings, which will help determine the causal links between the defect, the external load and the materials and technology used. Based on the similarity of structures, the technologies used and the character of external influences, the software system will make it possible to identify how probable it is that a risk will occur or a defect will further develop, offering the option to compare the situation in question with similar documented cases and recommending the optimum intervention. The system will provide tools for conservationists, administrators and owners of historical buildings for the documentation of defects in their buildings. At the same time, advanced artificial intelligence methods will provide users with knowledge accumulated in the form of a comprehensive overview of resolved defects, informing them of relevant preventive and renovative intervention techniques based on the similarity to the given case.

NAKI017 Technology for the maintenance and preservation of the Last Judgment mosaic and methods of renovation/preservation of medieval and archaeological glass.

The main objective of the project was the development of a technology for the maintenance and preservation of the Last Judgment mosaic and for its generalization. Partial objectives of the project included the monitoring of mosaic protective layers, a material survey (finding suitable materials and technologies for the protection of medieval glass - mosaics, stained glass, archaeological glass) and finding technology for the application of a protective coating and the verification of its stability.

NAKI027 Unified modular system for remote online monitoring of environmental parameters in depositories and expositions

The proposed project focused on the development of an integrated and, at the same time, modular system for the remote monitoring of cultural heritage objects through the online recording and processing of environmental parameters in depositories and expositions situated in historical buildings, museums, galleries, archives and libraries. The core of the project consisted of the development of a hardware platform and unified data structure which can be combined to enable the centralized processing of telemetry data with continuous monitoring of normal values of the parameters, further complemented by the development of specialized sensors. The general objective of the project was to improve the protection of cultural heritage objects from negative factors such as inappropriate climatic parameters, the presence of volatile organic compounds (VOC) and biological pests.