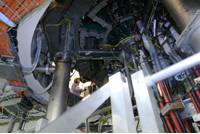

ITER will be the biggest-ever fusion device generating a plasma whose volume will be close to 840 m3 at 150 million ˚ C, ten times the temperatures at the core of the sun. To achieve these temperatures we would need powerful heating systems using high-energy beams, in order to push together the nuclei and trigger off a fusion reaction.

ITER will be the biggest-ever fusion device generating a plasma whose volume will be close to 840 m3 at 150 million ˚ C, ten times the temperatures at the core of the sun. To achieve these temperatures we would need powerful heating systems using high-energy beams, in order to push together the nuclei and trigger off a fusion reaction.

F4E, the European Union organisation managing Europe’s contribution to ITER, and Siemens, the global powerhouse operating in more than 200 countries, have started to collaborate on the development of three units of equipment that will host power supplies, whose requirements go beyond present industrial practices, as part of the ITER Neutral Beam Injectors (NBI), one of the ITER heating systems. One unit will be manufactured for a research facility operating in Italy, whose aim is to help scientists test the NBI components before they go into production mode for ITER. The other two units will be manufactured as part of the ITER powerful NBI system, designed to deliver 33 MW of power in order to inject neutral particles to the core its super-hot plasma. The works are expected to last seven years and their overall value will be in the range of 18 million EUR. Pietro Barabaschi, F4E acting Director, explained that “through this collaboration, a European global innovator will contribute to the largest international collaboration that is expected to influence the future energy mix”. Michael Krohn, Project Manager for High Voltage Decks and High Voltage Bushings at Siemens, stated that “our company is proud to be part of this international research project and to play an active role in the construction of units for the ITER Neutral Beam Injectors. We look forward to a fruitful collaboration”.

The scope of the contract:

Through this contract Siemens will design, manufacture and test three High Voltage units to

contain the power supplies of the NBI high energy beams that will heat up the ITER plasma.

Similarly, the High Voltage bushing assemblies, connecting the power supplies to the transmission

lines, procured by Japan’s Domestic Agency for ITER, will also be delivered through this contract.

Following the successful completion of the factory acceptance tests, the components will be shipped

and installed to different locations. The first unit will be delivered to the Megavolt ITER

Injector and Concept Advancement (MITICA) facility in Padua, financed by F4E, Japan’s Domestic

Agency for ITER and Italy’s Consorzio RFX, the host of the infrastructure where the NBI tests will

be carried out. The other two units will be delivered to ITER, in Cadarache, where they will be

integrated in with the other components of the NBI power supply system.

Think of the High Voltage decks as air insulated Faraday cages, distributed over two floors and

covering a surface of 150 m

2. They will contain transformers, power distribution systems, and control cubicles

weighing approximately 45 tonnes. The entire box with its structure will reach 100 tonnes and will

stand on tall post insulators more than 6 metres high above the floor. The units will be

manufactured in line with the seismic requirements applying to the respective installation

locations (Italy/France). The bushing design also presents a degree of novelty due to the very high

voltage insulation levels (1 MV) in a compact structure using SF6, a potent greenhouse gas used as

electric insulator. Siemens, responsible for the manufacturing of the bushing assembly, and

Hitachi, responsible for the production of the transmission lines, will have to collaborate closely

so that their components fit together in a seamless manner in order to operate.

http://www.iter.org

14 Oct 2015

Česky

Česky