In our laboratory, the following technologies are used for materials processing:

Plasma spraying of powders and liquids

- WSP-H, WSP

- ICP

Powder sintering

- SPS

Brief overview

Plasma spraying – method of preparation of protective layers or free-standing shapes. Deposited material, in the form of powder or liquid, is injected into plasma jet generated by a plasma torch, where it is melted and accelerated. After the impact of numerous droplets onto the component surface and their solidification, lamellar plasma sprayed coating is formed.

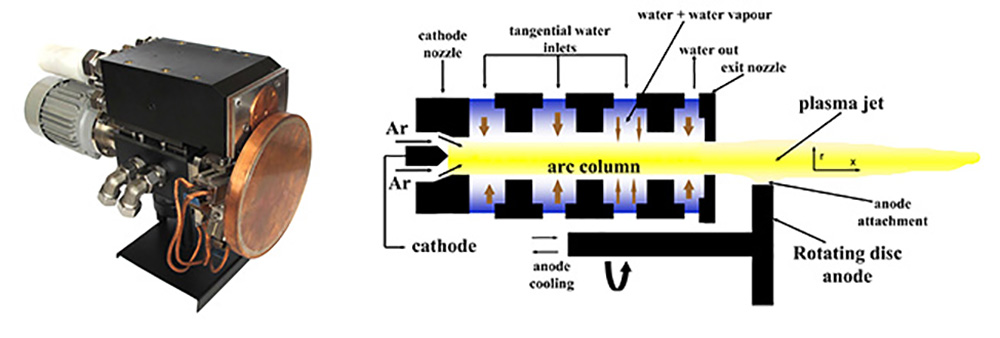

WSP-H – so called hybrid WSP (Water Stabilized Plasma) torch. In the WSP-H torch, plasma is formed by electric arc from water steam and gas (argon). This approach combines benefits of gas stabilization (non-consumable tungsten cathode) and water stabilization (high enthalpy, feed rates up to tens of kg per hour). WSP-based plasma torches are most suitable for spraying of large areas or deposition of thick coatings, preparation of free-standing parts and materials processing (including e.g. powder spheroidization). Both dry powders as well as liquids (suspensions and solutions) may be used as feedstock. The latest generation of WSP-H torches was developed in cooperation of our institute and ProjectSoft HK a.s. company. Typical materials sprayed in our laboratory include oxides (alumina, chromia, zirconia, titania, etc.), tungsten, silicates, carbides, minerals, and many others. We can also perform plasma spraying with the previous generation of WSP torch with graphite cathode.

WSP-H torch (left) and scheme (right).

ICP (inductively coupled plasma) torch, also called radiofrequency (RF) plasma torch. This torch may be also used for plasma spraying of coatings and materials processing. Plasma jet is generated in the chamber with controlled atmosphere or vacuum. Due to the elimination of oxidation risk, this technology is especially suitable for spraying of high-purity metals. Installation in the late 2016.

Spark Plasma Sintering (SPS), also called Field Assisted Sintering Technique (FAST) or Pulsed Electric Current Sintering (PECS), is a technology allowing fast compaction of both metallic and non-metallic powders. The powder is pressed in a die between two punches and heated by Joule heat generated by applied electric current. High heating rates and short sintering times allow for example elimination of undesirable grain growth during preparation of nanomaterials. Composite materials with tailored microstructure may be easily prepared by combination of two or more different powders.