Instrument description

SPN-100 is a double axis diffractometer employing elastically bent perfect Si crystal as a focusing monochromator. The instrument is designed for measurements of residual strains by accurate evaluation of positions of a selected diffraction peak from small material volume defined by a set of input and output slits. The diffractometer has a changeable monochromator take off angle and can be set and operated at a suitably chosen wavelength in the range 0.1 nm to 0.235 nm. In the case of α-Fe and γ-Fe samples, it usually operates at the neutron wavelength of 0.23 nm, providing a good resolution after diffraction on the α-Fe(110) and / or γ-Fe(111) lattices planes.

Layout

Parameters

|

Type of instrument |

Two-axis diffractometer |

|

Source |

LVR-15, 10 MW research reactor |

|

Beam tube |

Horizontal channel No. 4 |

|

Monochromators |

Bent Si(111) and Si(220) |

|

Take-off angle (range) |

30 – 60° |

|

Neutron flux on specimen |

2 × 105 cm−2·s−1 |

|

Incident wavelength |

1.0 – 2.35 Å |

|

Detector |

2-D Position Sensitive Detector, 3He, active area of 230 × 230 mm2, resolution 2 x 2 mm2. |

| Sample - detector distance | 1000 mm |

|

Beam defining optics |

Cd slits in the incident and diffracted beams |

| Specimen weight capacity |

XYZ stage: up to 50 Kg |

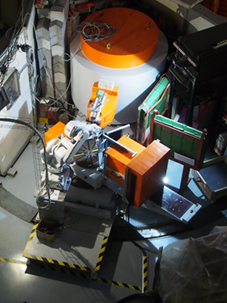

Sample positioning

For sample positioning, in addition to standard x-y-z translation stage, a six-axis robotic arm is available allowing more flexible manipulation of complex-shaped samples and automation of strain measurements.

|

|

| Robot studio for scan programming. |

Sample positioning by robotic arm (see video). |

|

| Samples on the XYZ stage. |

Selected publications

Correlation of magnetic properties and residual stress distribution monitored by X-ray and neutron diffraction in welded AISI 1008 steel sheets. Vourna, P., Hervoches, C., Vrana, M., Ktena, A., Hristoforou, E. (2015) IEEE Transactions on Magnetics, 51 (1), art. no. 7029219.

Residual stresses determination by neutron diffraction in a 100Cr6 chromium steel bearing ring. Rogante, M., Martinat, G., Mikula, P., Vrána, M. (2013) Kovove Materialy, 51 (5), pp. 275-281.

Residual stresses assessment in coated materials: Complementarity between Neutron and X-ray techniques. Rogante, M., Mikula, P., Vrána, M. (2011) Key Engineering Materials, 465, pp. 259-262.

Suppression of surface effect by using bent-perfect-crystal monochromator in residual strain scanning. Vrána, M., Mikula, P. (2005) Materials Science Forum, 490-491, pp. 234-238.

High-resolution neutron diffraction for nondestructive analysis of residual stresses in polycrystalline materials. Mikula, P., Lukáš, P., Vrána, M. (2005) Applied Mechanics and Materials, 3-4, pp. 331-336.

Applications for beamtime

All experiment proposals are evaluated on a continuous basis, they have to be submitted via the CANAM user portal.

Potential users are encouraged to contact instrument responsible before submission.