Perex

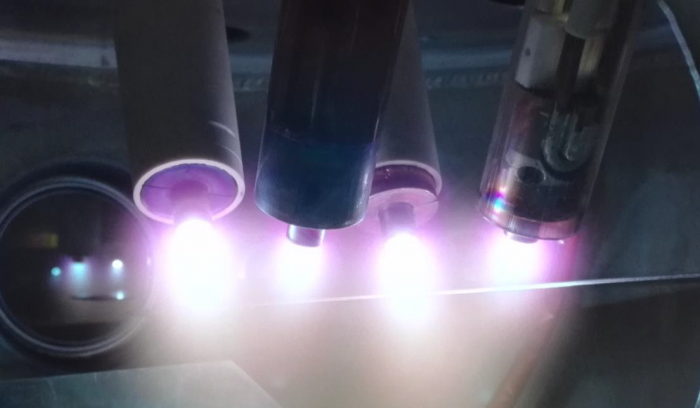

High-speed deposition system for homogenous sputtering of oxide thin films. The system uses several plasma nozzles mounted in one line, which work on the principle of hollow cathode discharge. High speed of deposition process is achieved by a combination of non-reactive sputtering inside the hollow cathode with thermal evaporation of hollow cathode material.

Text

Features and benefits

- Due to the absence of a target poisoning effect, the system exhibits extremely high deposition rates for oxides, nitrides and other reactively sputtered materials in comparison with a classical DC magnetron

- Due to the combination of sputtering with thermal evaporation, the system exhibits a much higher deposition rate in comparison with a regular hollow (cooled) cathode discharge

- Due to the absence of magnetic field, the system exhibits a very high deposition rate for ferromagnetic materials (iron, cobalt, nickel) and their compounds in comparison with magnetron sputtering.

Specification

- An extremely high temperature of individual nozzles (around 1500 a total heat flux to the substrate can reach 100 W per nozzle (1.5 W/cm2)

- Thermally sensitive substrates must be cooled during the deposition

Applications

An industrial and scientific institution

Contact

Technology transfer office | tto [at] fzu [dot] cz

Mr. Oskar Lazansky | e-mail: lazansky [at] fzu [dot] cz | mobile: +420 725 015 339