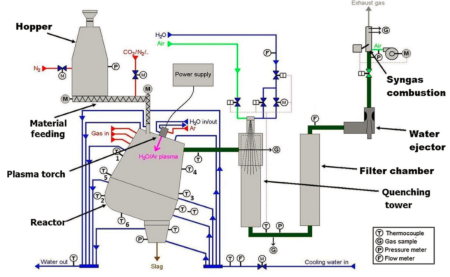

Reactor PlasGas

Our flagship reactor, built in 2004 in cooperation with industrial partners from Belgium and from the Czech Republic. The reactor is contiually upgraded to cope with new projects. The internal refractory lining is able to withstand temperatures up to 1500 °C and there is a possibility to dose wide variety of solid, liquid and gaseous fuels or materials to be treated. So far, we performed experimental research of plasma gasification, pyrolysis and reforming of wood, sawdust, pellets, lignite, waste plastics, polyethylene, polypropylene, simulated medical waste, refuse derived fuel (RDF), pyrolytic oil, methane, simulated natural gas and ethanol. The produced gas is sampled directly at the output of the reactor and then can be cooled to a desired temperature by water spray system. Recently a high-temperature ceramic filter was installed which enables us to filter the produced syngas from high loads of carbon particles at temperatures up to 700 °C. The reactor is maintained at slight underpressure by a powerful water ejector system. The gas is then safely combusted in a flare.

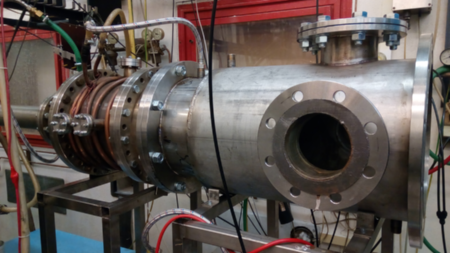

Kinetic reactor

Reactor specially designed for the study of the kinetics of the gasification, reforming and pyrolysis processes takink place along the axis of the reactor. Reactor is smaller than PlasGas reactor and it is equipped by the special water/argon plasma torch with lower power.

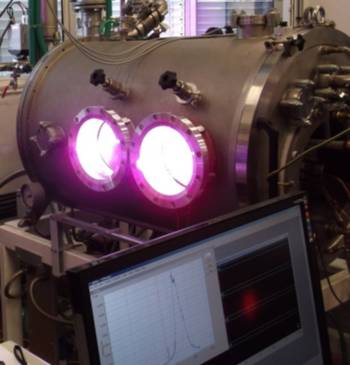

Low-pressure reactor

Designed to study the effect of ambient pressure on arc characteristics and jet properties, to study the supersonic jet with extremely low plasma and to investigate the utilization of supersonic jets for plasmochemical applications and for plasma spraying.

Reactor for treatment of perfluorinated compounds

This reactor was specially designed for treatment of substances containing fluorine.

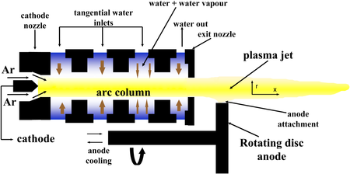

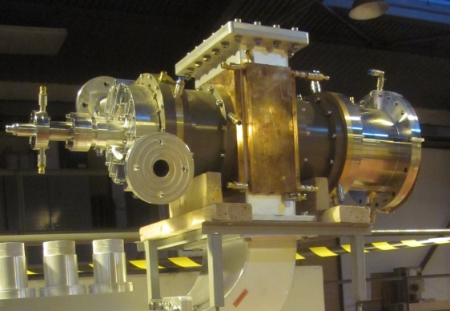

WSP-H – so called hybrid WSP (Water Stabilized Plasma) torch

In the WSP-H torch, plasma is formed by electric arc from water steam and gas (argon). This approach combines benefits of gas stabilization (non-consumable tungsten cathode) and water stabilization (high enthalpy). Application of water as a plasma forming medium, together with its high enthalpy, brings apparent advantages for gasification and pyrolysis, in comparison with commonly used air plasma. The latest generation of WSP-H torches was developed in cooperation of our institute and ProjectSoft HK a.s. company. Input power up to 160 kW can be applied. This torch is also succesfully used for plasma spraying (see https://www.wsp-h.com/ and site of Department of Material Engineering http://www.ipp.cas.cz/vedecka_struktura_ufp/materialove-inzenyrstvi/)

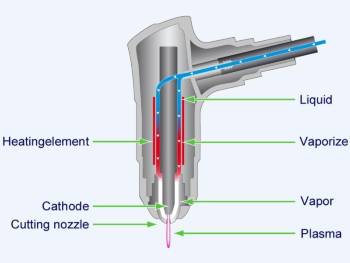

Steam plasma torch

The plasma torch TransCut 300 was developed by Fronius International GmbH, Austria. The liquid mixture of water and ethanol is heated and produced vapour is used as a plasma

forming gas. This torch was originally designed for plasma arc cutting. It has input power up to 5 kW, i.e. much lower than WSP-H. We use it for demonstration of steam arc plasma technology and for testing the plasmochemical processes in small scales.

Microwave plasma torch

This new torch with power up to 75 kW is currently installed in our laboratory. It is supposed to be used for gasification and pyrolysis applications.

Diagnostic

- High-speed camera Photron FASTCAM SA-X2 with maximum frame rate 1080 000 fps and minimum exposure time 0.25 µs; the camera is synchronized with the Cavilux HF laser with wavelength 810 ± 10 nm; the pulse power of the laser is up to 500 W and the pulse duration can be varied between 50 ns and 10 µs – study of fast processes connected with plasma and its interaction with particles of treated material can be performed.

- Optical spectrometer Triax 552 equipped with gratings 300, 1200 and 3600 grooves/mm giving spectral resolutions 0.16 nm/pixel, 0.036 nm/pixel and 0.0098 nm/pixel respectively. The output spectrum is detected by the iCCD detector with 1024x256 pixels.

- Optical spectrometer Flame - Ocean Optics for low resolution overview emission spectra in the range 200-1100 nm

- Quadruple mass spectrometer – online gas and plasma sampling in various positions in reactor volume and determination of local composition of plasma and gas.

- FT-IR spectrometer Matrix – concentration measurement of output gases

- Enthalpy probe Tekna connected to quadruple mass spectrometer – measurement of plasma enthalpy, temperature, composition and flow velocity in the positions where heat flux does not exceed limiting values for probe destruction.

- Borescope camera with gas flow protection of optics – allows optical insight into the hot and chemically active environment in reactors.